4D Reservoir Monitoring for Production and CO2 MMV

A very common 4D reservoir monitoring practice is to utilise seismic acquisition to survey a producing oil or gas field before and during production to estimate the changes to reservoir properties such as seismic velocity and density as hydrocarbons are replaced by water. As such, 4D seismic reservoir monitoring enables understanding of the changes to properties in producing oil and gas reservoirs, both spatially and in time. The 4D seismic method is proven for oil producing reservoirs and is today a major contributor to optimised oil production and increasing recovery rates.

The lifting cost of incremental hydrocarbons recovered as a result of 4D data is low, hence 4D knowledge is very important and increasingly urgent. Going forward, it is imperative for the industry that we continue to improve the 4D method in order to ensure remaining hydrocarbons can be produced as reliably and efficiently as possible.

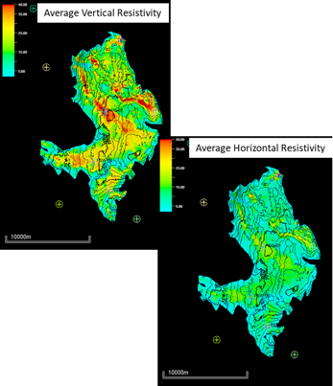

CSEM field measurements are highly sensitive to changes in resistivity that is directly related to changes in saturation, hence 4D resistivity monitoring holds promise in improving 4D success, especially for quantitative gas and CO₂ monitoring.

Images courtesy of Petrobras